A core drilled anode system may be a solution if the existing tank bottom has not yet reached the point where a full tank bottom is warranted.

The options to replace existing depleted cathodic protection systems or inoperative reference cells on existing tanks are rather limited.

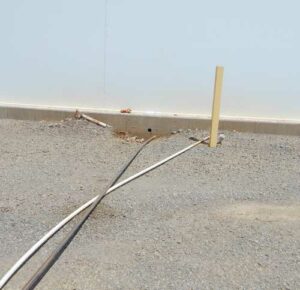

If the existing tank bottom has not yet reached the point where a full tank bottom is warranted, then core drilling provides a solution.

MATCOR has developed a core drilled anode installation procedure that allows us to safely install additional anodes and replacement reference cells that can add service life and improve CP monitoring.

MATCOR’s proprietary hydrovac displacement and wet sand delivery replenishment assures an intimate contact between the anode or reference cell and the sand around it.

The exact length to which core drilling can reach varies at each core drill location thus requiring field adjustments for the best performance possible to extend the life, improve the current distribution or provide additional cathodic protection monitoring capabilities.

Core Drilled Anode System Benefits

- Fast, easy installation

- No welding, cutting or assembly of anode required – completely factory assembled and tested system ready to install

- Systems available for new and retrofit tanks

- Superior current distribution

- Reliable Kynex® factory installed connection technology with redundant power fed from two directions – no under tank splices