This article provides an overview of pipeline corrosion in the United States, the two categories of corrosion in pipelines and the primary methods of prevention.

Corrosion of Pipelines in the United States

The United States has over 2,225,000 kilometers of pipelines, the vast majority of which are transporting oil and natural gas. No other country comes close—Russia is a distant second with approximately 260,000 km of pipelines. The US Pipeline network consists of hundreds of public and private companies that own and operate these pipelines within a national regulatory framework managed by the US Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA). While pipelines have proven to be exceptionally efficient and very safe—pipelines are roughly 70 times safer than trucks1 and 4.5 times safer than rail2—the aging network of pipelines continues to be of concern because much of the nation’s pipelines are at least 50 years old and getting older.

Pipeline Corrosion Prevention Mitigates Devastating Failures

Corrosion is one of the biggest problems contributing to leaks and ruptures of pipelines. Corrosion is the natural process where materials made from metal electrochemically react with the environment and deteriorate. Without proper engineering and preventative maintenance, this deterioration from the natural process of corrosion will result in an increasing frequency of pipeline incidents. The good news is that with proper pipeline monitoring and maintenance, corrosion is completely manageable. Operators can utilize existing technologies to ensure the integrity of these critical assets and prevent damaging failures.

Two Categories of Corrosion in Pipelines

Pipeline corrosion can be broken down into two primary categories. Internal Corrosion, which causes approximately 12% of all incidents, occurs on the inside of the pipeline, while External Corrosion, which results in approximately 8% of all pipeline incidents, occurs on the outside of the pipe.

Pipeline Corrosion Protection Strategies for External and Internal Corrosion

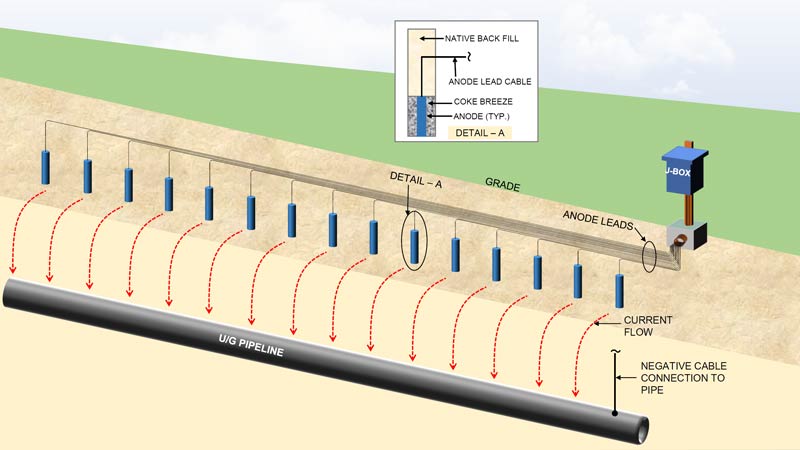

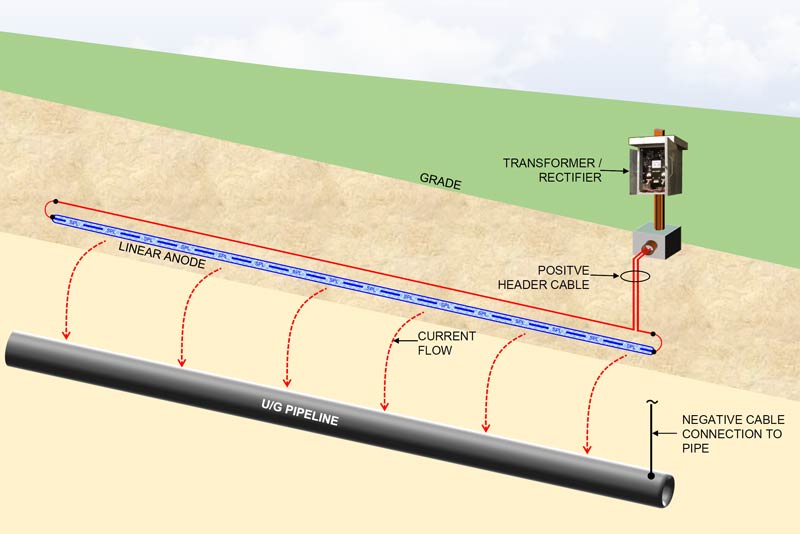

Two primary mitigation strategies are employed to prevent external corrosion of pipelines:

When these mitigation strategies are properly employed, monitored and maintained, steel pipelines can last indefinitely. While this sounds simple, pipeline coatings are never perfect and are themselves subject to damage during construction and degradation over time, while cathodic protection is a complex process that requires continuous monitoring and extensive testing, combined with regular maintenance to be effective.

Internal corrosion, in most cases, is a result of contaminants naturally occurring in the product being transported by the pipeline. Common contaminants include oxygen, hydrogen sulfide, carbon dioxide, chlorides, and water.

Many variables can affect the nature and extent of a particular internal corrosion reaction on a pipeline:

- Contaminant concentrations

- The combination of contaminants within the pipeline

- Operating pressure and velocity

- Pipeline geometry and holdup points

- Operating temperature

- Other factors

The primary pipeline internal corrosion prevention strategies include:

- Controlling or minimizing contaminants prior to transporting them in the pipeline

- Internal pipeline coatings

- Injection of corrosion inhibitors

- Increased frequency of internal pipeline cleaning to remove the accumulation of contaminants

For controlling both external and internal corrosion, regular monitoring and testing programs combined with the appropriate mitigation strategies, are a critical part of any pipeline integrity management program. When performed properly, corrosion can be effectively controlled, assuring that pipelines remain safe from corrosion indefinitely.

1 propublica.org – Pipelines Explained: How Safe are Americas 2.5 Million Miles of Pipelines?

2 fraserinstitute.org – Pipelines are the Safest Way to Transport Oil and Gas

To get in touch with our team of cathodic protection and AC mitigation experts for more information, to ask a question or get a quote, please click below. We will respond by phone or email within 24 hours. For immediate assistance, please call +1-215-348-2974.

Contact a Corrosion Expert