AC mitigation is the process of designing and applying pipeline grounding systems to:

- Prevent voltage spikes during fault conditions

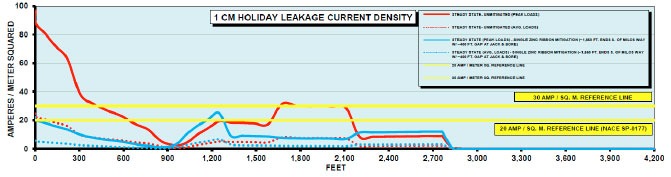

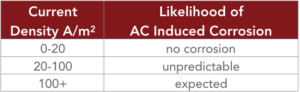

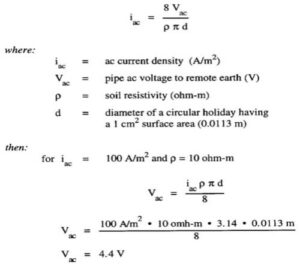

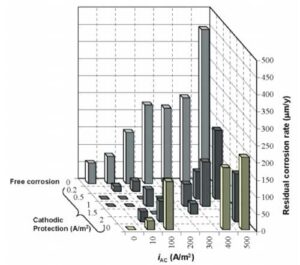

- Reduce AC current density to protect against AC-induced corrosion

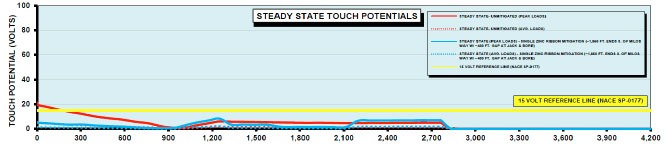

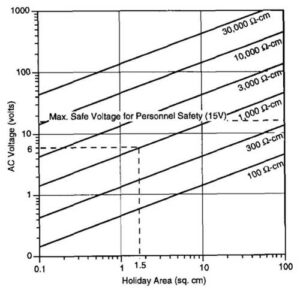

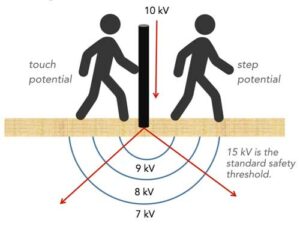

- Maintain AC step and touch potentials below 15 Vac to protect personnel from shock hazards

Pipelines that parallel overhead high-voltage AC transmission power systems are subject to AC interference. AC interference has several potential adverse impacts on the safety of personnel and pipeline integrity. Assuming that these conditions exist, there are several measures that can be taken to mitigate the AC interference present in a pipeline. These AC mitigation strategies are detailed in various international standards including two AMPP (formerly NACE) standard practices: SP0177-2014 Mitigation of Alternating Current and Lightning Effects on Metallic Structures and Corrosion Control Systems, which primarily focus on safety for operators and other people working on or near pipelines subject to AC current and lightning events, and SP21424-2018. This addresses the guidelines and procedures for risk assessment, mitigation, and monitoring of AC-induced corrosion on pipelines.

There are four basic approaches to mitigating AC Interference. These mitigation strategies are:

1. Fault Shielding

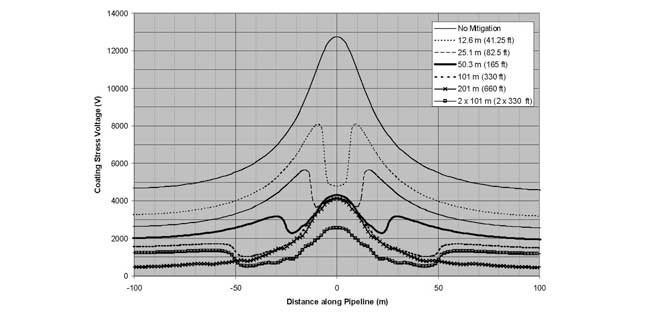

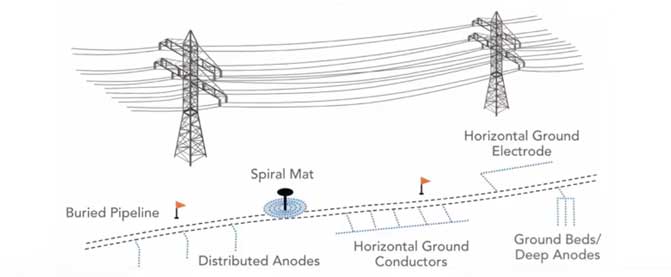

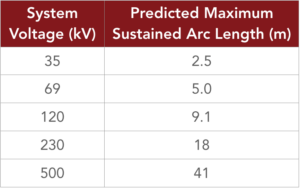

One of the primary concerns with high-voltage AC transmission systems parallel to buried pipelines is the risk that a fault condition at a transmission tower could result in the rapid discharge of fault current near the pipeline. This could lead to direct current arcing in soil – rare but very damaging. More common is the rapid ground potential rise that subjects the pipeline coating to large voltage gradients that result in coating damage. Fault shielding is a suitably designed grounding system that is installed between the tower footing and the pipeline that acts to shield the pipeline and shunt harmful currents away from the pipeline by providing a low resistance path to earth. This typically takes the form of a parallel shielding wire, either copper or zinc, connected to the pipeline.

2. Gradient Control Mats

When high levels of AC voltage are present on a pipeline, either during a fault condition or as the result of an inductive coupling during normal steady-state operations, personnel in close proximity to and/or touching any above ground or exposed appurtenance are at risk for electrical shock step or touch hazards. Installing a gradient control mat, which is a system of buried bare conductors, typically galvanized steel, copper, or zinc, connected to the structure, provides localized touch and step voltage protection by creating an equipotential area around the appurtenance.

3. Lumped Grounding Systems

Lumped pipeline grounding systems consist of shallow or deep localized grounding conductors that are connected to the structure at strategic locations to reduce the AC voltage level along the pipeline. This provides protection to the structure during steady-state or fault conditions from the nearby electric transmissions.

4. Gradient Control Wire

Gradient control wire grounding systems function the same as the lumped grounding system. With this type of system, long continuous grounding conductor(s) are installed horizontally and parallel to the pipeline. They are strategically located and sized to reduce the AC-induced voltage along the pipeline during steady-state or fault conditions from the nearby electric transmission.

For mitigating high levels of AC-induced voltage along a pipeline, gradient control wires are the most common form of AC mitigation. Hybrid systems that combine lumped grounding systems with gradient control wires are also common. Regardless of the type of pipeline grounding system used, all of these AC mitigation approaches involve installing a grounding device to the affected structure to allow AC-induced current and fault current to be quickly discharged off of the pipeline.

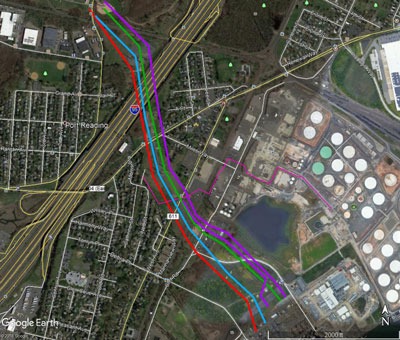

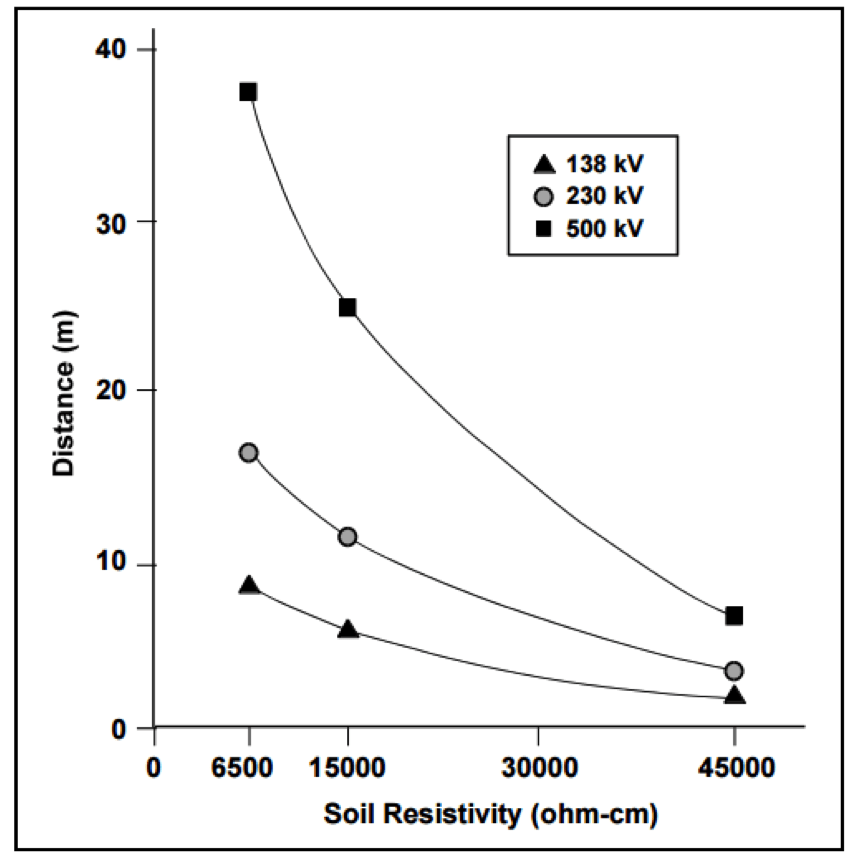

AC Modeling

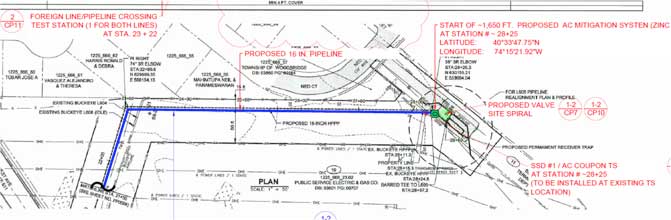

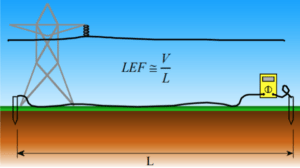

Prior to installing an AC mitigation system, it is common to use complex AC modeling software to evaluate the impact of fault currents and estimate the steady state induced currents that can be expected along the pipeline. This information is used to determine the quantity and location of mitigation required based on numerous factors, including the resistivity of the soil, the physical characteristics of the pipeline, the operating parameters of the HVAC transmission system and the spatial distances between them.

Engineered AC Mitigation Systems

Based on a thorough assessment of the pipeline and high voltage AC transmission system interaction, including modeling results when available, an AC mitigation system is designed by experienced engineers familiar with the mitigation strategies detailed above. This engineered AC mitigation system would detail the quantity and location of grounding installations required for a specific application. MATCOR’s MITIGATOR is an example of this type of AC mitigation system.

Other features of an engineered AC Mitigation system include:

Special Backfill

It is quite common to install the grounding conductor in a special backfill material. The purpose of the backfill can vary depending on the conductor material chosen and the type of backfill used. The benefits of various types of AC mitigation backfill include:

- Enhanced surface area – conductive backfills such as carbon or conductive concrete are used to effectively increase the surface area of the grounding conductor reducing the overall resistance to earth.

- Corrosion/Passivation Protection – some backfills are designed to protect the grounding conductor from corrosion or passivation of the conductor that could adversely affect the life or impede the performance of the grounding conductor.

- Hydroscopicity – some hygroscopic backfills readily attract and retain water from the environment, helping to maintain a low uniform resistance around the grounding conductor.

Solid State Decouplers

These devices are almost always used in conjunction with AC mitigation systems and are usually installed wherever the grounding system is connected to the pipeline. These devices are designed to allow AC current to flow off the pipeline during steady-state or fault conditions while blocking all DC current. This effectively isolates the pipeline’s cathodic protection (CP) system from the AC mitigation system, preventing the mitigation system’s grounding conductors from taking CP current from the pipeline.

AC and DC Coupons and Remote Monitoring Test Stations

Regardless of which mitigation strategies are being used, it is important to

design and install a monitoring system to be able to affirm compliance with the AC Mitigation criteria established in SP21424-2018. This includes monitoring both AC and DC current densities. The monitoring system should be designed to collect representative data at regular and continuous intervals. This usually includes remote monitoring of AC corrosion criteria.

MATCOR provides complete AC Mitigation solutions including design, supply of materials, turnkey installations, and comprehensive testing services.

If you are looking for help with AC Mitigation systems or services, please contact us. We will respond by phone or email within 24 hours. For immediate assistance, please call +1-215-348-2974.

Contact a Corrosion Expert