We’ve talked about AC Interference and we’ve talked about AC Modeling. The topic of our newest training video is AC Mitigation. The video is about 9 minutes long and we’ve included timeline indicators below so you can easily find your topic of interest in the video.

The goal for AC mitigation is to reduce your fault condition stress values to protect against stress coating damage and arcing potentials (arcing is less common because you need to be very close to the pipeline for arcs to appear). This includes:

- Reducing current density below your threshold value. Typically in the US we use 20 amps per meter squared for a one CM2

- Maintaining AC step and touch potential below 15 volts so that people working in and around pipeline areas are not subject to shock due to a fault condition

AC Modeling Aids in Predicting Conditions [0:55]

We use AC modeling to provide predictions and look at the mitigated and unmitigated conditions. Some cases warrant building a model, in other cases we can use “ad hoc” methods (such as experience) to come up with an effective AC mitigation plan.

Learn more in our AC Modeling Video.

AC Mitigation Schemes [1:14]

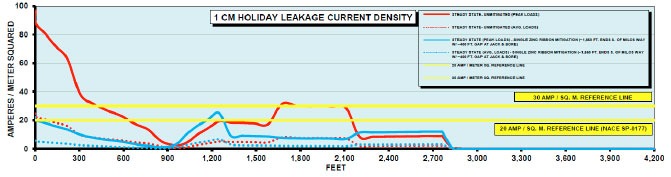

For our example pipeline application, AC modeling results show some locations to be concerned about where the 20 amps per square meter threshold is exceeded. These locations are indicated below, where the red line is above the yellow 20 amps per square meter reference line. What do we do to mitigate this risk?

In this case, we’re going to put in a gradient control line in the areas of concern next to the pipe. This is a grounding system that attaches to the pipeline so that AC being picked up by the pipeline has a place to go. The coating system is “too good” with only a few small holidays, which means all of the current being picked up tries to rush out of those few small holidays. This is how you end up with AC induced pipeline corrosion.

By putting in a grounding system at strategic locations along the pipeline, we can reduce the AC voltage being picked by discharging it and giving it a place to go.

There are several ways to design an AC mitigation system but they are all basically grounding systems. Our solution in this case is shown as the blue line representing a grounding mitigation line.

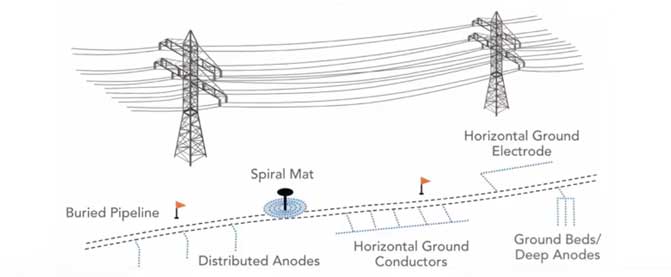

Typical AC Mitigation Strategies [2:23]

- Install a gradient control mat at locations where people can touch the pipeline

- Maintain safe pipeline to power line separation distances to avoid arcing problems during fault conditions

- If separation distances are too close, include a shield that picks up current as it is dumped to the earth and deflects away to protect the pipeline

- Provide grounding of the pipe to the earth to dissipate current being picked up during steady-state conditions

What is a gradient control mat? [3:00]

A gradient control mat is a simple device that is connected to the pipeline to protect workers from step and touch potentials.

It is connected to the pipeline appurtenance where a person can touch the pipeline, and extends out enough so that somebody standing on it will not have that step and touch potential. Since it is connected to the pipeline, the entire gradient control mat has the same potential as the pipe.

As soon as I step on to that gradient control mat, I don’t have a voltage difference between me and everything else. Even if I touch the pipe, the ground below me is at the same voltage as the pipe, so no current flows through my hand, to my body and into the ground.

It is a fairly significant effort to install a gradient control mat but they protect people close to that appurtenance. Once they are above that gradient control mat, touching or being near the pipeline is not going to cause a problem. Current doesn’t flow unless there is a voltage difference. You can actually be in an environment where there is high voltage all around you, and as long as you are at the same potential (or equipotential), there is not going to be any current flow, and current is what can injure or kill you.

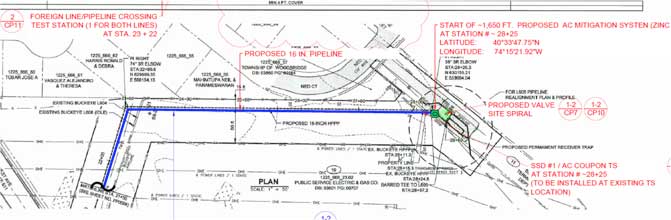

AC Mitigation Case Study [4:33]

In the case study shown, a pipeline runs parallel for 8 km to a transmission line, with the towers next to the pipeline. In this case the towers are too close so we use a zinc ribbon shield wire to protect from fault conditions. The zinc ribbon picks up the current and dissipates it before it can cause damage to the pipeline.

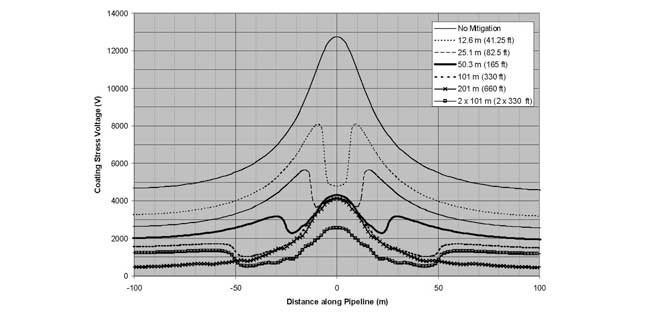

AC Mitigation Reduces Coating Stress Voltages

The chart below shows the effects without any mitigation, where you can see the voltage spike where it goes above 12000 volts of coating stress voltage.

You can see once various forms of mitigation are added, stress voltage drops below the limits. And depending on the type of coating, there’s a certain voltage limit that coating can withstand.

Pipeline Grounding Methods [5:46]

- Spiral mat at pipeline valve stem location

- Anodes in the earth that are connected to the pipeline; these become grounding rods for the pipeline

- Horizontal ground conductors, connected at various lengths to the pipeline (gradient control line mitigation)

- Deep anode ground beds

Deep Anode Case Study [6:25]

Deep anode ground beds are a little more expensive, however they a good solution in high resistance areas where you can’t discharge current into the ground effectively near the surface.

We did a project out west in the desert of the United States, where a new pipeline parallel to a transmission line was picking up AC voltage. In the very dry desert environment there was nowhere for this current to discharge. Grounding rods next to the pipeline do not work well in this case because the environment is so dry. We drilled holes 1000 feet into the earth and installed grounding cells. These were run up to the surface and connected to the pipeline to dissipate the AC voltage being picked up.

[7:11] There are a variety of ways to ground a pipeline; AC mitigation is basically how we ground the pipeline effectively.

AC Mitigation Materials [7:16]

The most common materials used for pipeline grounding include:

- Zinc ribbon laid parallel to the pipeline

- Bare copper, which is used predominantly in the corrosion industry

- Engineered copper grounding systems; The MATCOR MITIGATOR® is an example of this type of system

- Conducrete® systems where conductive concrete is used to enhance the earth’s surface area

AC Mitigation and Grounding Concerns [7:58]

- Ease of installation

- Performance

- Life, how long is it going to last

- Cost

Optimum AC mitigation [8:12]

- The AC mitigation system is only as good as the modeling, so it is critical to ensure that modeling is accurate

- Gradient control lines parallel to the pipeline are the most common grounding system used currently, although there are also quite a few locations using deep anode systems

- For fault conditions, short lines at tower footings tend to be the most effective AC mitigation strategy