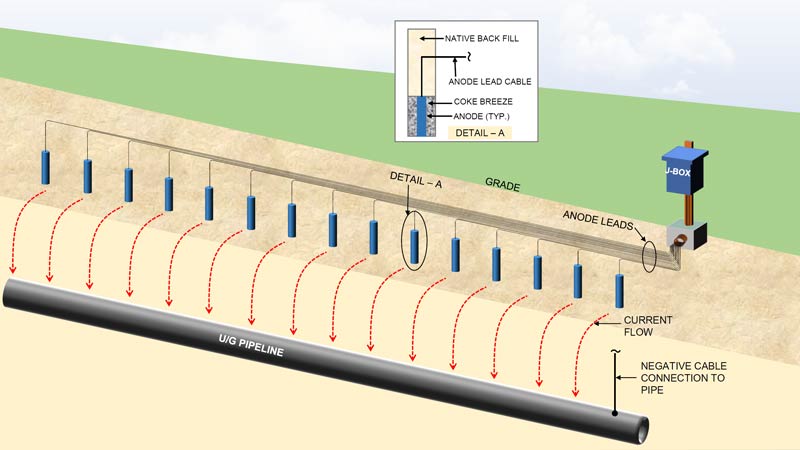

A common cathodic protection system approach is the use of a shallow horizontal anode bed. These are typically defined as an anode system consisting of a series of multiple individual anodes installed either vertically or horizontally at a depth of less than 15m (50ft) and connected to a single power source. These are particularly effective in areas where drilling deep anode beds is not feasible or practical.

The typical anode used in shallow anode bed applications is an impressed current anode. These can be high silicon cast iron, graphite anodes or mixed metal oxide tubular anodes. The anodes may be pre-packaged in a canister filled with coke backfill, or they can be installed in a vertically drilled/augured hole or a continuous horizontal trench with backfill installed around the bare anode. The anodes can be installed in parallel to a common header cable or can have individual leads all routed to a cathodic protection junction box and connected in parallel inside the junction box.

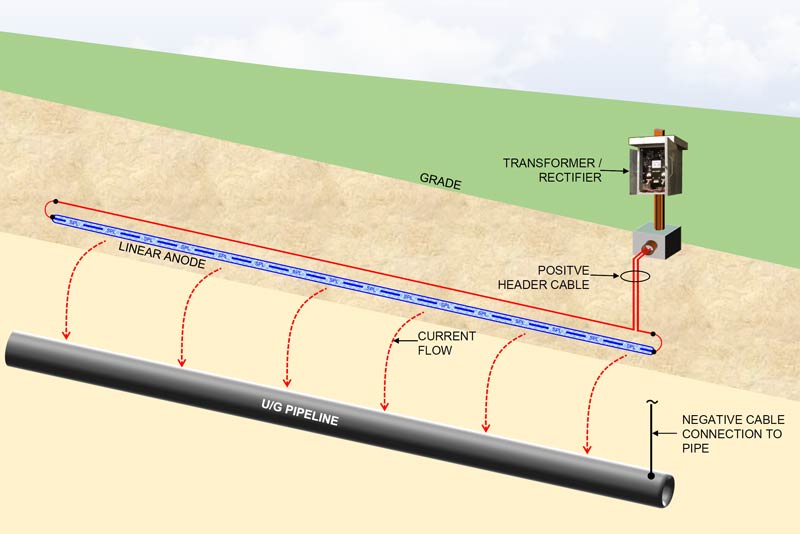

A New Approach: Continuous Linear Anodes

Another approach that is gaining acceptance in the corrosion industry is the use of a single continuous linear anode as an alternative to multiple individual discreet anodes that are field connected to form an anode bed. There are several advantages to using a single continuous linear anode to create a shallow horizontal anode bed:

Advantages of linear anodes for shallow horizontal anode beds

- Ease of installation

The use of a single continuous linear anode assembly can significantly reduce installation time by eliminating numerous field splice connections of multiple individual anodes to a header cable. - Reliability

The entire linear anode assembly is factory manufactured and tested with internal factory connections that are more reliable than a field connection. The assembly is designed with an internal header cable for redundancy and can be manufactured with an integral external return header cable, eliminating all field splicing and connections. - HDD Installation

The use of a linear anode for shallow anode bed design allows for the use of HDD (horizontal directional drilling) to install the continuous anode assembly. This can significantly minimize the installation footprint and greatly reduce installation time and costs. This also allows for a deeper installation to facilitate locations where surface activities such as deep tilling farming operations might preclude a shallower anode system installation. - Cost Effectiveness

The use of linear anodes can be extremely cost effective, resulting in a much lower cost installation. This is especially true when considering the overall cost per amp year given the longer design life of mixed metal oxide based linear anode systems.

MATCOR has extensive experience designing and installing shallow horizontal anode beds, including the use of our HDD installation crews and state-of-the-art equipment to minimize surface impact in sensitive areas.

Contact us at the link below to find out if a linear anode cathodic protection system is right for your application.

Contact a Corrosion Expert